Online Support is an end-to-end service solution for Roche Diagnostic customers when dealing with technical issues.

Project Overview

Every time you have a blood test, your sample is sent to a lab and placed into one of the advanced analyzers. Chances are, that machine is leased by Roche - the global leader in diagnostic equipment. Yet despite their dominance in the field, Roche has limited visibility into the experience of lab staff or the challenges their face while using the analyzers.

I joined the newly formed Digital Transformation

team to uncover challenges and opportunities in the labs, and ultimately co-create solutions that truly meet customer needs.

team to uncover challenges and opportunities in the labs, and ultimately co-create solutions that truly meet customer needs.

My role

User research, UX/UI design, prototyping

Built the product from zero

Workshop facilitator

Results

Co-designed flexible access to Roche Customer Support 24/7

Reduced issue resolution time

Increased lab automation and process standardization

The Process

Finding opportunities through understanding customer experiences

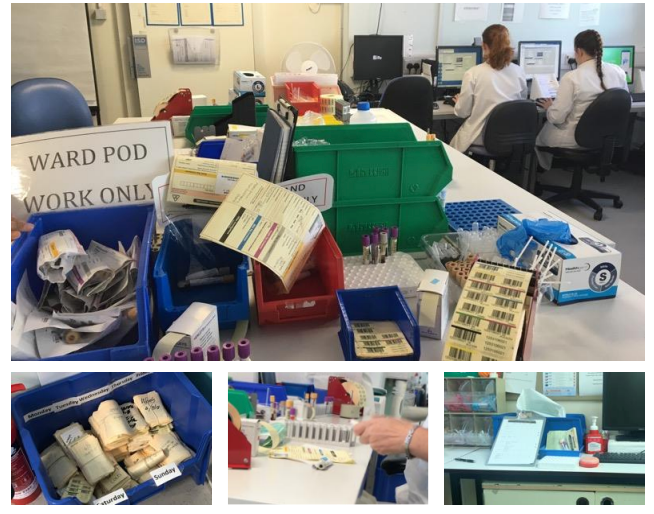

We kicked off the project with discovery research focused on core lab customers and their end-to-end journey — from sample picking to delivering final results. Alongside three project managers and another UX designer, we visited 5 hospitals across the UK to experience firsthand what happens inside the labs and uncover valuable insights.

Our main research objective was to identify key moments of frustration and delight for different lab staff and to map all their touchpoints with Roche.

We primarily used contextual inquiry approach which allowed us to observe people in their actual work environment. It was important to spend time where the work happens — silently observing interactions and asking questions only when needed to understand why certain actions were taken. In each lab, we also conducted in-depth interviews with 3-4 key employees to complement our observations.

We observed a lab’s reality which is defined by a gap between low and high technology

Lack of empowerment is frustrating

Lab staff often feel restricted when it comes to solving technical issues with analyzers. Many report insufficient training and a lack of accessible materials to help them maintain the instruments on their own terms.

Lab staff often feel restricted when it comes to solving technical issues with analyzers. Many report insufficient training and a lack of accessible materials to help them maintain the instruments on their own terms.

Technology adds complexity

Hardware and software used by the labs seem to create additional work instead of streamlining workflows. To cope with system limitation, staff rely on workarounds and hacks - but these often lead to even more effort and inefficiencies.

Hardware and software used by the labs seem to create additional work instead of streamlining workflows. To cope with system limitation, staff rely on workarounds and hacks - but these often lead to even more effort and inefficiencies.

One of the many user journeys we created based on our research findings (along with unique personas).

All of the crafted materials were essential to prepare Design Thinking workshop.

All of the crafted materials were essential to prepare Design Thinking workshop.

How might we empower lab operators and get their analyzers up and running again?

After several days of consolidating our research insights, we organized a workshop to share our findings with a broader group. We invited not only management and developers but also technical experts — including field engineers who regularly visit labs and repair analyzers. Their perspective was critical to create a solution that could truly make an impact. Our three-day Design workshops focused on exploring concepts to help labs troubleshoot and resolve issues more independently. One key insights from the engineers was that many simple to moderately complex problems could be solved by the lab stuff themselves if only they had the right guidance. This would also ease the burden on engineers who often travel to fix issues that could be resolved in just 5 minutes.

At the time, the only support option was to contact a helpline which often led to long wait times and disrupted daily lab duties. In more complex cases, labs sometimes had to wait days for an engineer to arrive on site.

I like to summarize all the most promising workshop ideas in the form of rough mockups. In this way, it's easier to get back to some more advanced or challenging ideas, gather the initial impressions from users, as well as further influence business stakeholders.

During our visits, we noticed that nearly every lab kept a paper logbook — usually a notebook or folder — documenting issues for each machine. These logs included what went wrong, when it happened, and who fixed it. They also served as a reference point, storing instructions shared by helpline or field engineers so lab personnel could look them up later. But because this knowledge was captured on paper, it was often hard to retrieve. Notes were unstructured, rushed, and difficult to search through — making it challenging to find solutions to recurring problems.

This was our epiphany: most lab issues were never formally reported to Roche, yet they were a crucial part of the analyzer's usage history. As a result, we decided to create a simple MVP — a tablet app that would make it easy to log issues directly in the lab. The app was designed not only to record problems quickly, but also to serve as a first line of support, especially for recurring issues.

Creating the Digital Logbook

Making it easy for lab staff to document issues

With clear MVP goals in place, we begin working on user flows and exploring the simplest way to log an issue in the app. It was crucial to remember that many lab employees aren't highly tech-savvy, so the entire process had to be quick and clear.

UX played an essential role in driving this behavioral shift — helping lab staff move away from paper-based solutions and adopt a digital tool that could integrate into their daily routines.

UX played an essential role in driving this behavioral shift — helping lab staff move away from paper-based solutions and adopt a digital tool that could integrate into their daily routines.

As our small team was co-located in Brighton for the first month of work on MVP, we spent a lot of time together drafting and improving the app workflow.

One of the first tested designs for creating / updating ongoing issue

Continuous user research

Customer interactions played a crucial role in shaping the product throughout the entire project. Early on, we learned that logging an issue requires more advanced input and the ability to share details with Roche specialists. As we continued visiting new labs, it became clear that not all facilities could afford tablets. While they were the preferred option in the first labs we visited (thanks to their larger screens for viewing photos and troubleshooting steps), this insight led us to also develop a responsive mobile version of the app.

Together with my fellow designer, I was responsible for conducting and documenting all lab visits and remote usability tests. However, every team member, including developers, had the opportunity to join the research sessions. This inclusive approach resulted in a dedicated and committed team united by one goal: making life easier for lab staff.

It was fantastic to observe our users effortlessly exploring the app!

More advanced version of the form where we also included an ability to request a call back from support.

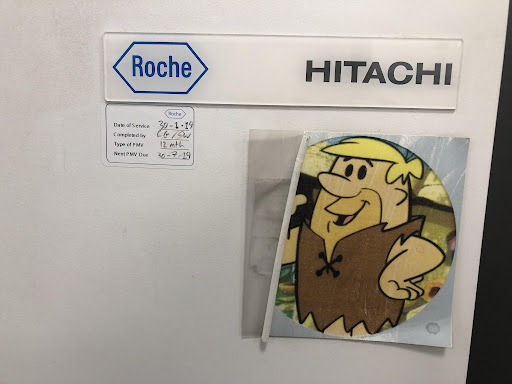

"Barney is down!"

Are we speaking our customers' language?

Are we speaking our customers' language?

Our lab visits continued — not just to test the usability of our solution but also to seek inspiration for future iterations. One insight stood out: especially in larger labs machines of the same type are often given unique names or nicknames. This happens because the only official identifier is a long, complex ID number. The physical order of the machines matters too, as they're usually connected in a sequence, forming a "line".

We began exploring ways to reflect this natural language and naming logic within the app, while still ensuring all necessary data could sync properly with Roche systems. Some lab managers suggested a simple onboarding flow that would let them easily customize machine names and reorder elements as needed.

Once we validated the feasibility of overwriting names and confirmed the associated workflows, I moved on to designing the user interface. I like to start with a low-fidelity sketches to facilitate the conversations and alignment within the team. From there, I build an interactive prototype to test this onboarding tool directly with lab managers.

Interactive prototype of "Lab Setup" built in Axure for the purpose of usability testing

From paper logbook:

"Our current paper-based logbook is inefficient and takes hours every week of additional work."

To Digital Logbook:

"I prefer the iPad version over the paper logbook. It’s easier to browse through history. I can quickly find existing issues by typing the alarm code."

Official Online Support

Following the success of our MVP, we rolled out the application to selected labs in Germany and Spain. Over the next few months, we continued working in agile sprints, incorporating feedback and requirements from these new users. As a result, the product expanded significantly and now includes features such as:

- logging new issues and reviewing the status of ongoing ones

- resolving problems using previously documented solutions

- access to official Roche tutorials

- requesting helpline support

- chatting directly with the engineer

-a dashboard for managers to track the most common errors

-...and more :)

- logging new issues and reviewing the status of ongoing ones

- resolving problems using previously documented solutions

- access to official Roche tutorials

- requesting helpline support

- chatting directly with the engineer

-a dashboard for managers to track the most common errors

-...and more :)

One of the last "vision" prototypes created in Sketch/InVision

Reflections

I spent 13 months with the team on what became one of the most impactful and rewarding projects in my 3+ years at Roche. During this time, I had the chance to apply wide range of UX techniques and wear many hats, while also actively influencing the product's strategy and vision. I'm extremely happy and proud that we were given the chance to adopt a full design thinking framework, keeping users front and center to uncover insights that drove meaningful change. Today, Online Support is available to lab users across much of Europe, the US, and Asia.